Production-as-a-Service explained: Easy entry into Printed Electronics manufacturing

Companies across the world are developing innovative printed electronics products that require...

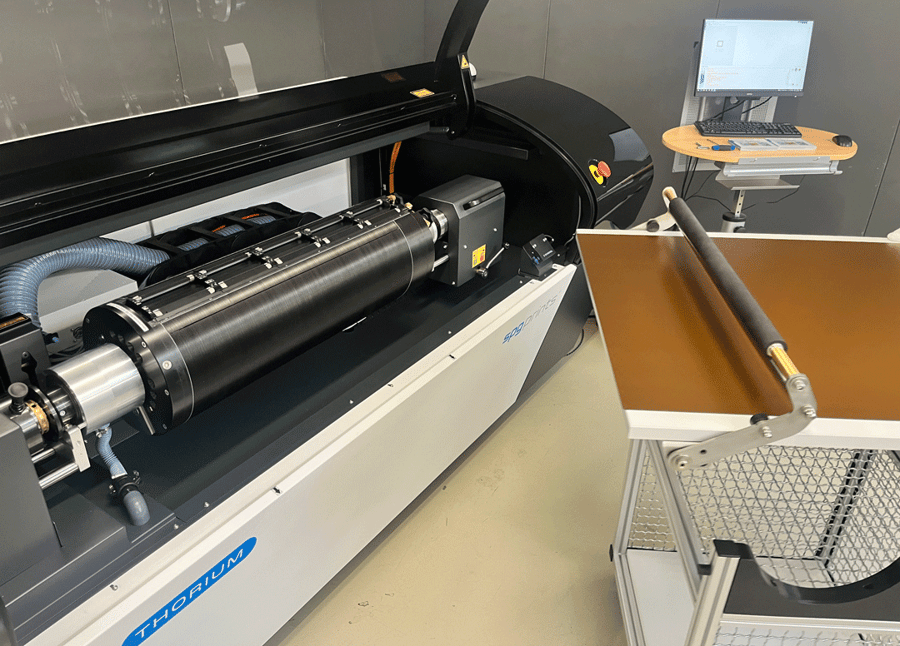

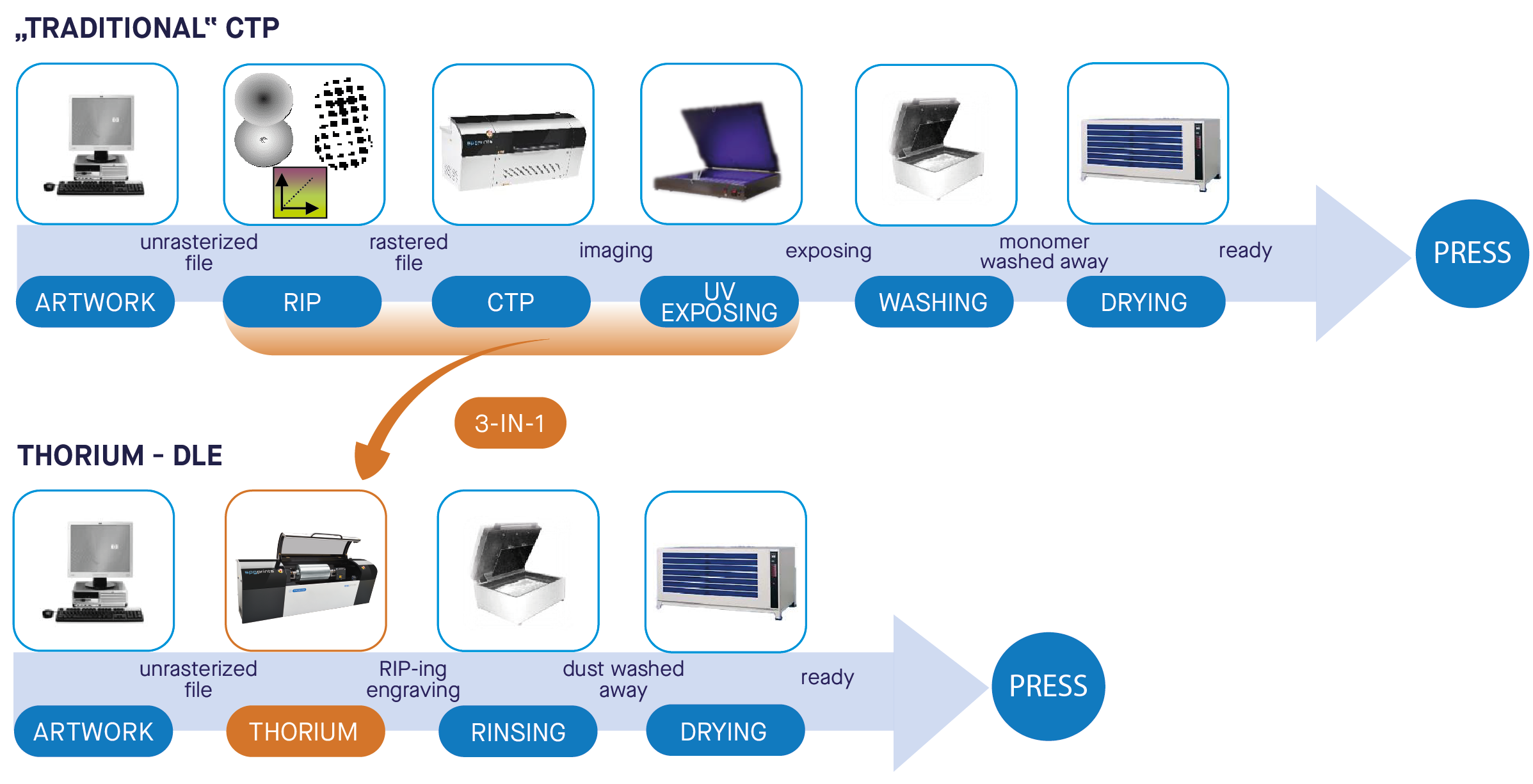

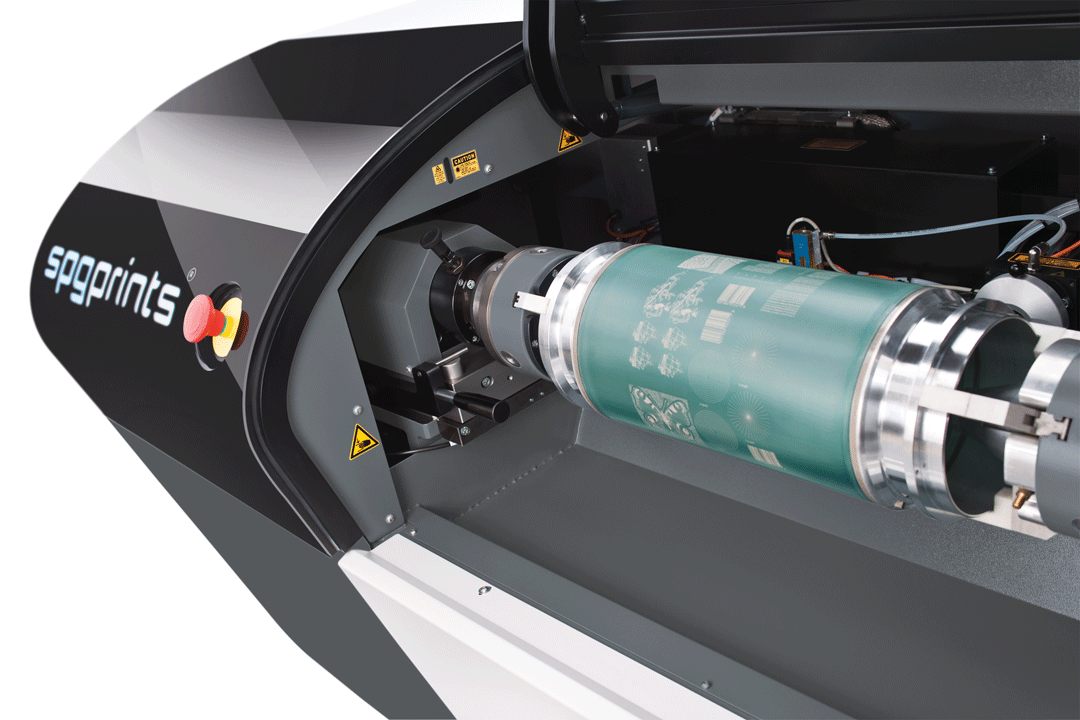

Read moreWith the THORIUM, printers can now produce the highest quality print with a shorter, solvent-free process, by longer runs and multiple cost saving potentials in the printing process.

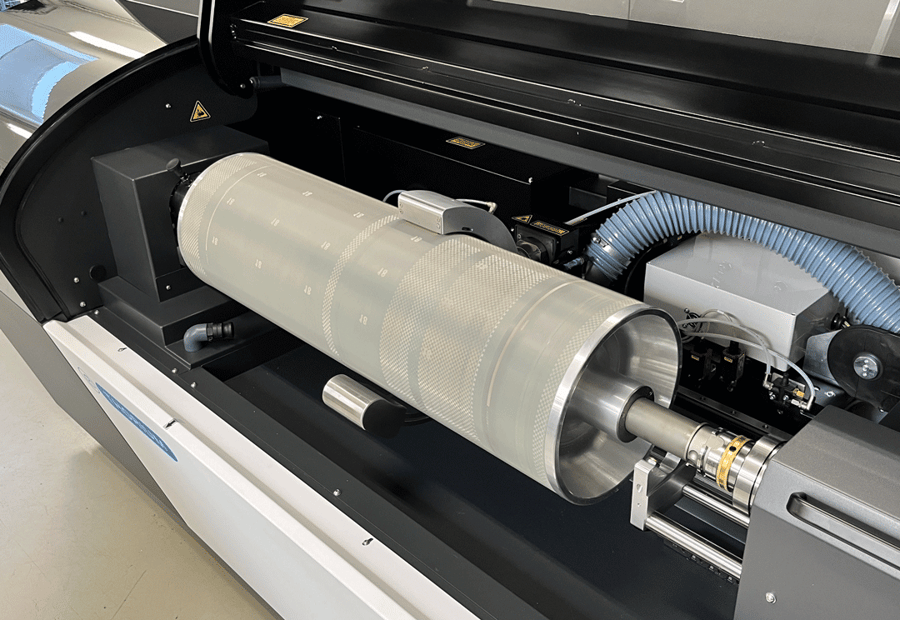

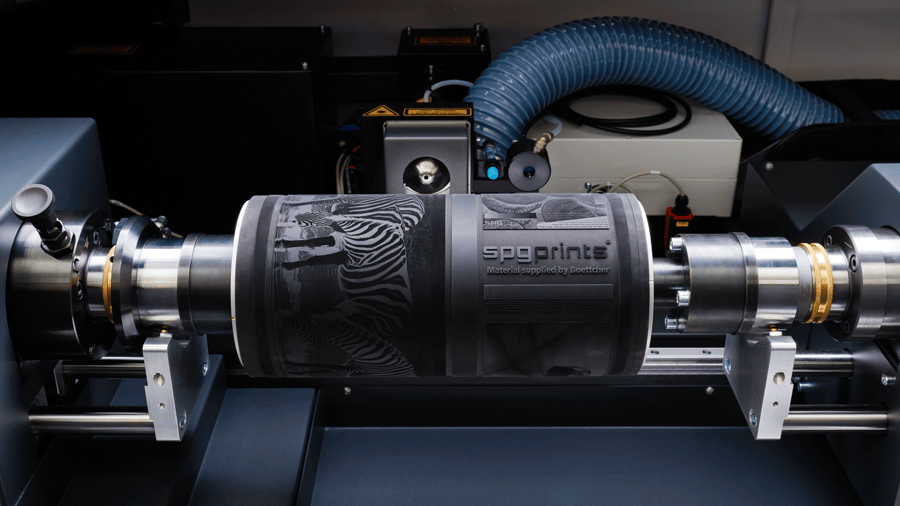

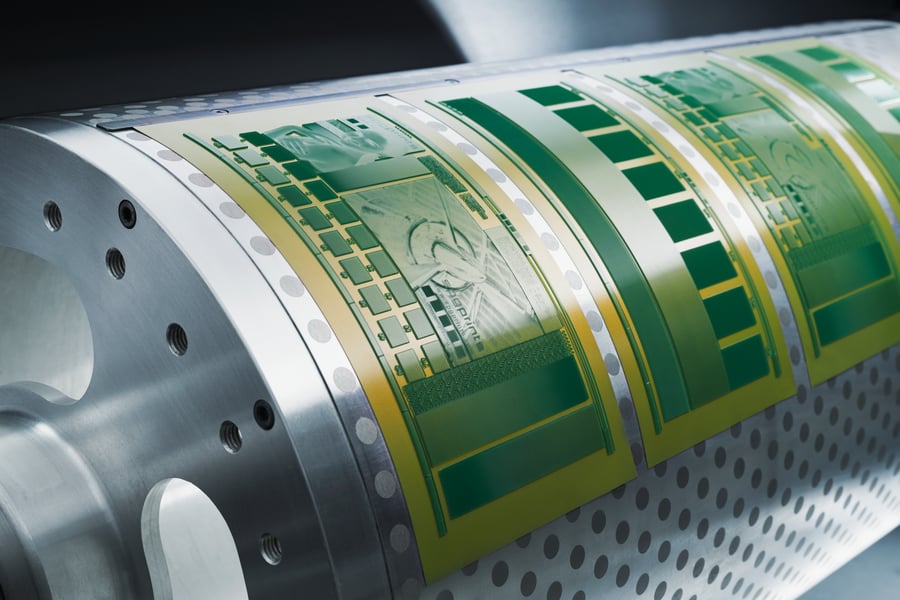

The THORIUM direct laser engraver is a cutting-edge solution that produces high-quality print materials for various applications. Whether you’re in the dry offset, security printing, screen printing, flexo, or embossing industry, THORIUM delivers exceptional results. It's versatility extends beyond conventional boundaries, making it an indispensable tool for modern pre-press.

Laser

sealed CO2 laser

Resolution

variable up to <10.160 dpi

Cylinder mounting surface

max. 900mm x R1256

Sleeve diameter (outside)

60 - 400 mm (3,4 - 15 inch)

Sleeve width

150 - 950 mm (5,9 - 37,4 inch)

Dimension machine LxWxH

3400 x 1300 x 1315/1860 mm

“The THORIUM direct laser engraving system, which replaces our successful HELIOS, is a proven solution for creating high-quality printing forms across various applications.”

With THORIUM, you can seamlessly handle four different printing forms: Dry Offset, Intaglio polymer plates, flexographic varnish plates, and seamless endless screens—all using a single piece of equipment. Moreover, THORIUM achieves this without the need for chemicals, resulting in significant cost savings.

The system employs a unique single-step dry process to eliminate non-printing areas by simply burning away the polymer. There is no need to handle or store chemicals. After engraving, the customer doesn’t need to further process the print form or take any additional steps.

Lower operational costs

A perfectly coordinated software (in-house developed CAD/CAM) and hardware achieves streamlining workflows, reducing process steps, and allowing multiple print forms to be used on a single machine. Additionally, the new CO2 laser generator eliminates the need for process gas and integrates an automatic standby mode, resulting in significant operational cost savings.

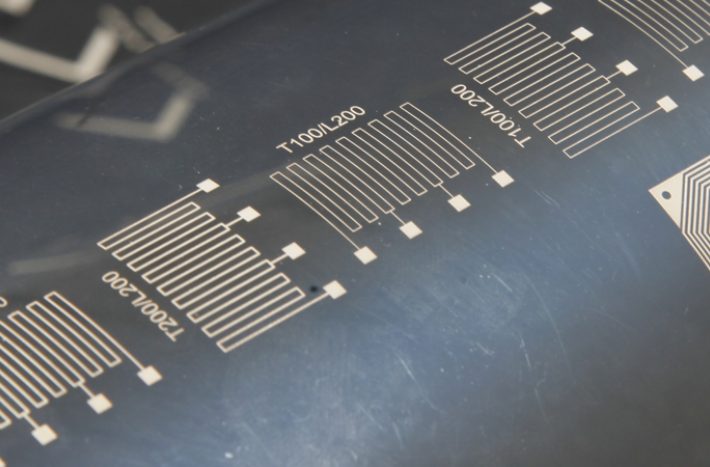

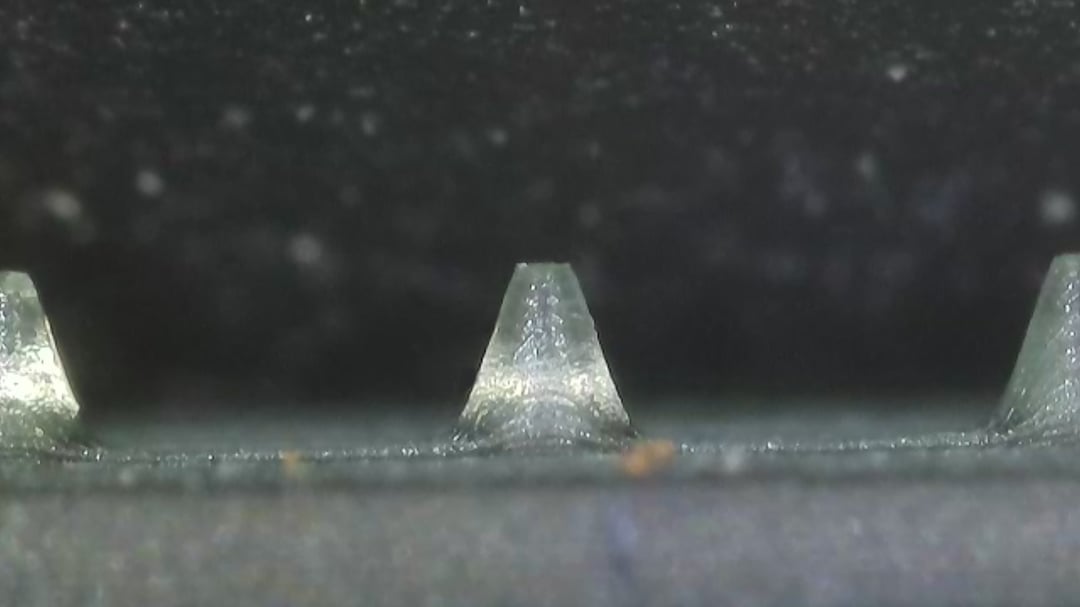

The THORIUM boasts the capability to engrave forms at an impressive resolution of 10,160 dpi—exceeding the limits allowed for the plates themselves in terms of dot size and resolution.

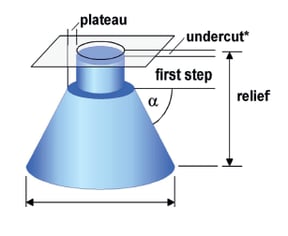

A unique Active 3D®-RIP system, developed in-house, enables three-dimensional dot shaping for printing forms. This innovative approach prevents over-impression of smaller elements by positioning them below the printing surface, ensuring they print consistently alongside larger elements, resulting in exceptionally fine results with extreme accuracy and repeatability.

Many different applications can be supported with SPGPrints pre-press systems:

Check our industrial pre-press solutions here

Our experts would like to share their knowledge and experiences with you.

Read all about industrial applications in our blogs.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.