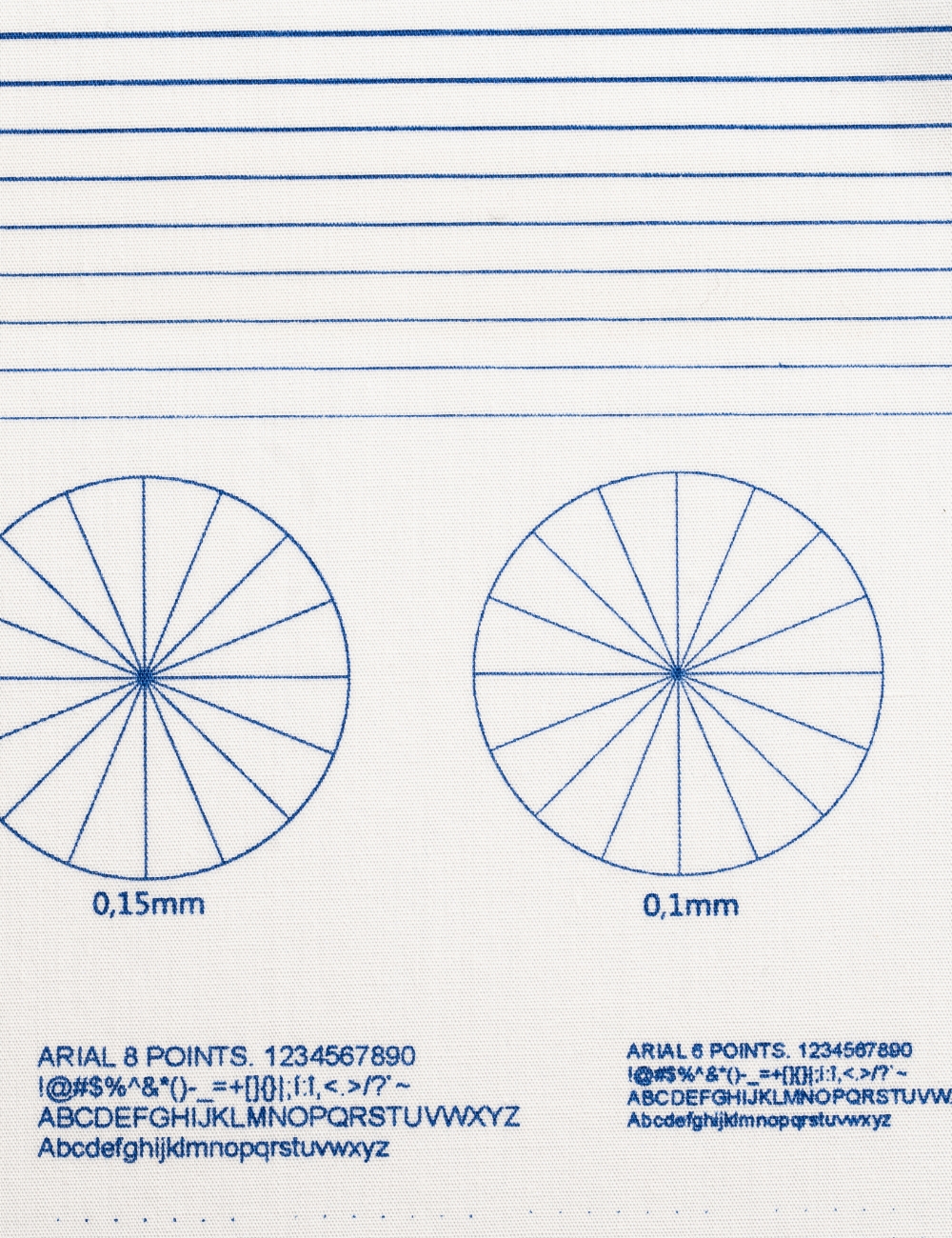

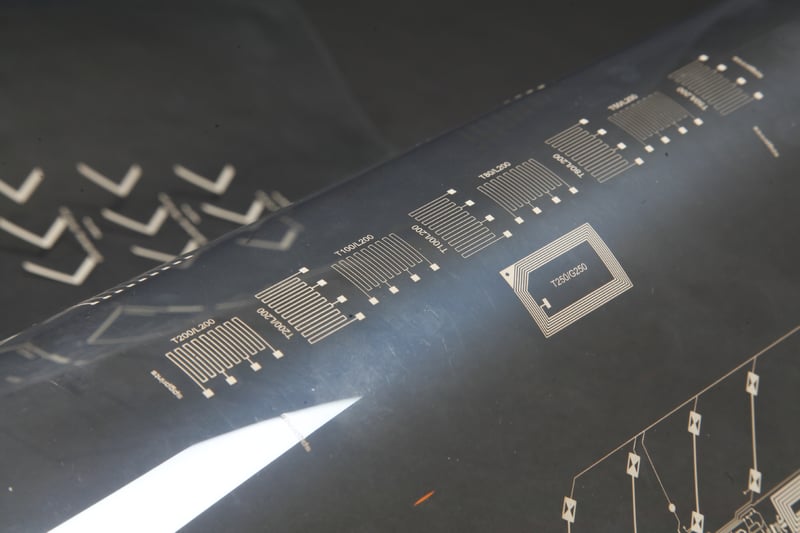

Find your screen type for the job.

Choosing the right screen is critical to make sure your prints look like the artwork. These artworks inevitably contain halftones, geometric designs or fine lines, blotches and flat tones. Knowing the printing quality various screens can deliver, helps you to make a sound choice!

To see the impact of screen choice, click the visuals below.