How to improve your Rotary Screen Printing process without changing the printing process itself

Discover how to reduce process costs and improve quality, without changing your process itself.

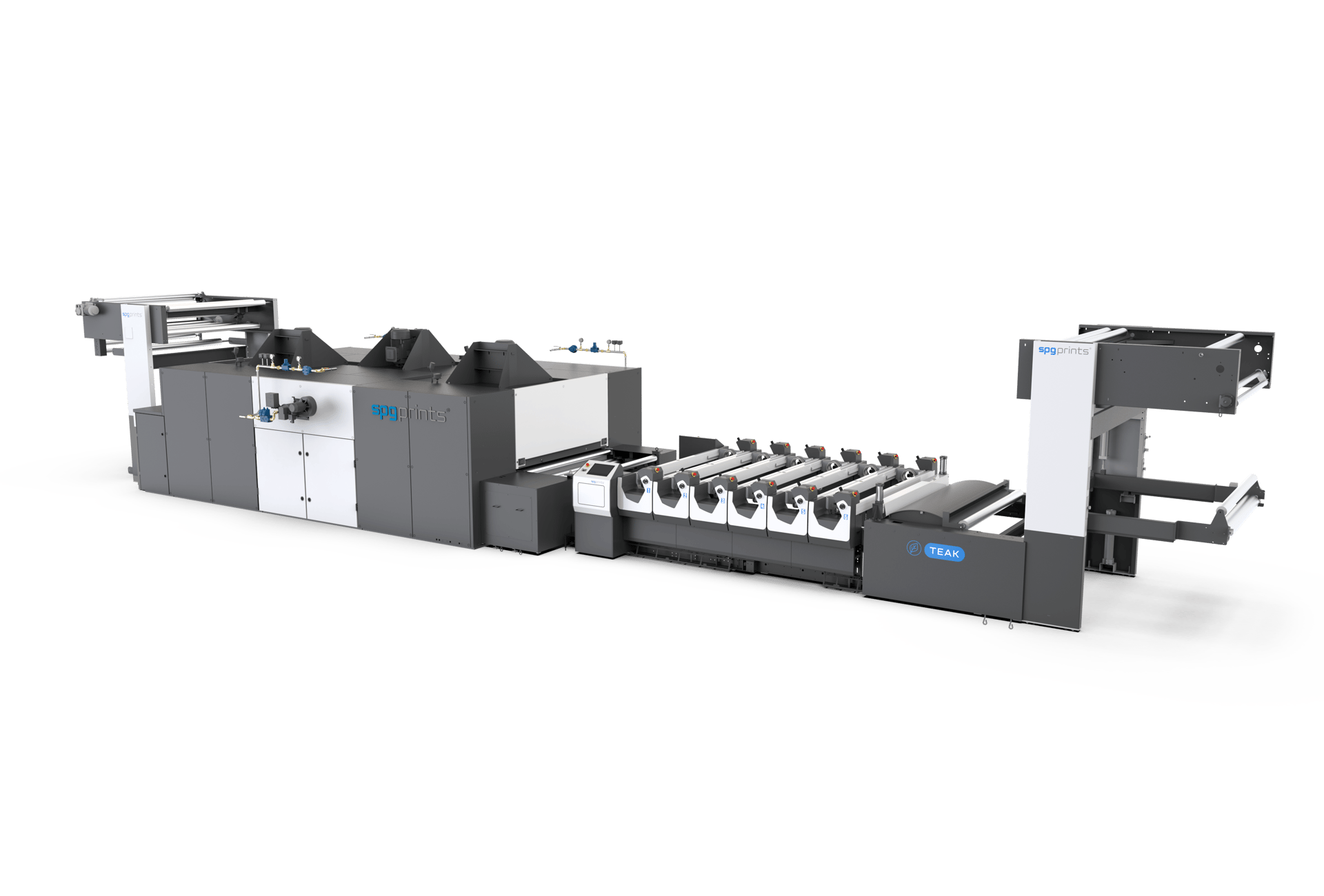

Read moreA new-generation rotary screen textile printing system, based on more than 70 years of experience.

Model width

1620, 1850, 2250 and 2450 mm

Number of colours

Up to 24

Speed

Up to 80 meters per minute

In-feed

Knit or woven from big batch or trolley

Screen Drive

Individual drive

Printing Heads

Closed, lifetime-lubricated bearing

Squeegee System

Combination of blade and roller squeegee

Operating and colour side

Left and right side flexibility

Gluing System

Wet (with airflow squeegee blade) and thermoplastic gluing as option

Repeat Possibility

Universal repeat from 640, 725, 819, 914 and 1018 mm

Colour Pumps

Pneumatic / SB-7 reversible colour pumps

Dryer

Apollo-II dryer with 2, 3, 4 and 5 sections

Discover how you can grow your textile business with high-quality rotary screen fabric printing equipment. We are passionate to boost your production, so you and your customers are satisfied with high quality products.

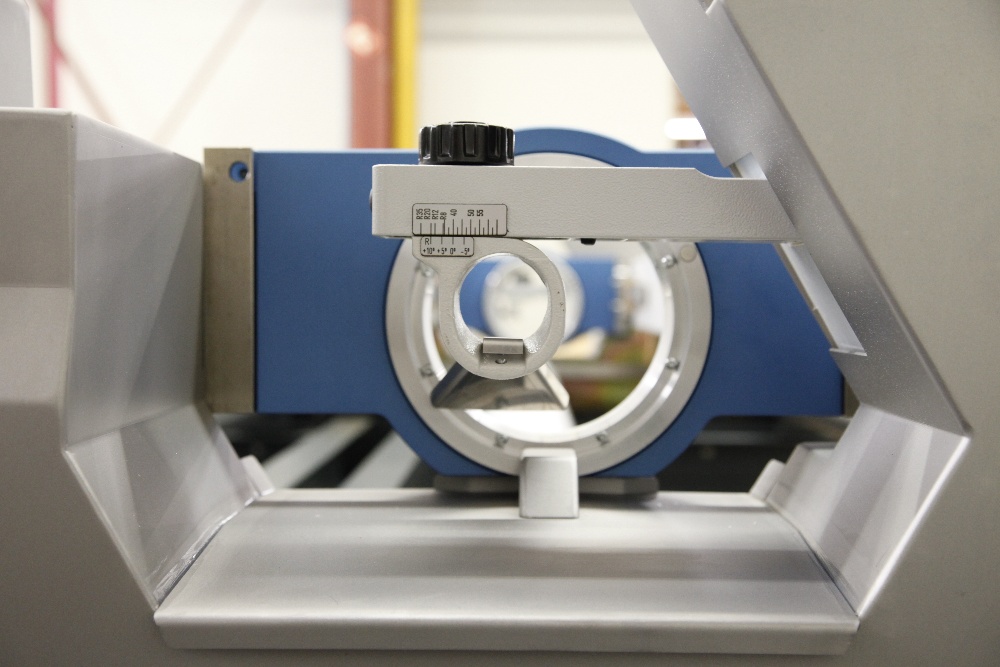

The unique Teak eco-paste system in combination with rubber ball and reversible colour pumps, takes out the maximum amount of colour paste left in the squeegee pipe. With the pump water savings package, the pumps and tubes are initially washed by recycled water and then rinsed with fresh water. This fresh water will again be re-used as recycled water.

Benefits of the Teak rotary printing textile system:

We can help with your textile print challenge. We’ve got you covered.

We are driven to provide cutting-edge solutions to your textile printing challenges. Request a test run for your design today to discover what we could do for your company and your customers.

Read more about our various Rotary Printing Systems for fabric printing, like Teak.

We can help with your textile fabric rotary printing challenge. To ensure the highest quality for you and your customers. We’ve got you covered.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.