Choosing the Best Digital Textile Inks for Different Fabrics

Exploring Different Ink Types: Characteristics and Best Uses Acid Inks Acid inks are renowned for...

Read moreHaving the right ink that allows for high-quality and durable prints is essential. Reactive inks enable this need for printing textiles, commonly used for cotton and viscose.

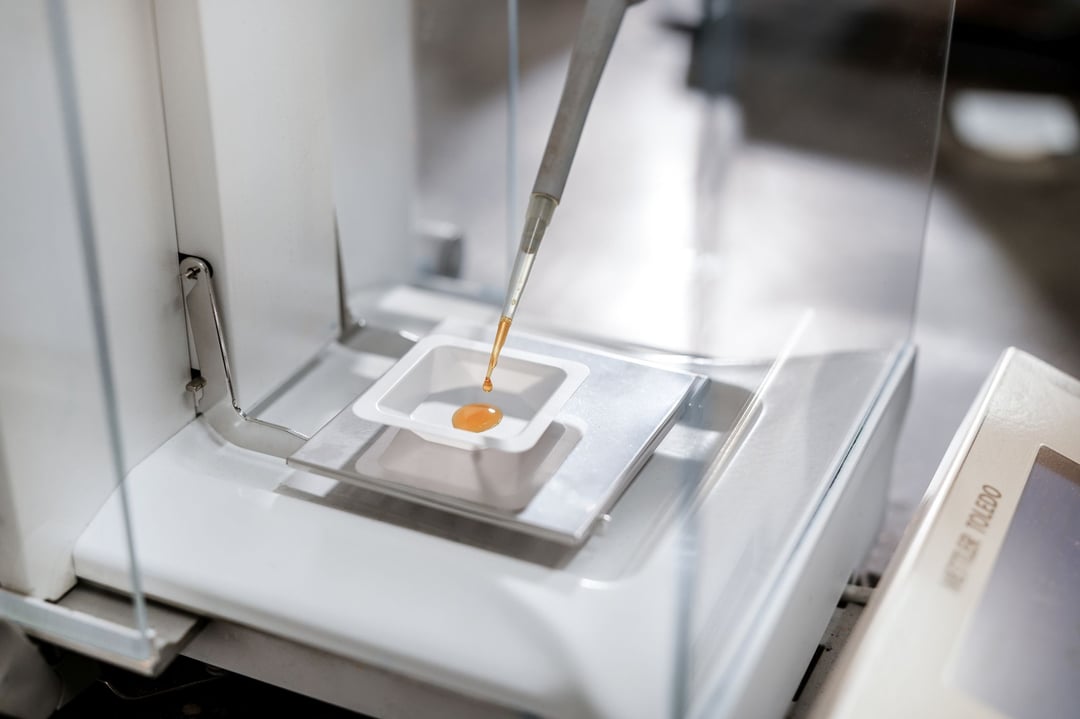

Reactive inks are a type of ink used in textile printing processes. These inks are specifically designed to bond chemically with natural fibers, such as cotton and viscose. When the textiles are being steamed, this chemical reaction makes sure that the color molecules are bonded to the fiber, resulting in vibrant and durable prints.

This type of ink is particularly favored for its ability to create intricate and detailed designs on textiles while maintaining good color fastness and high wash fastness. They are often used in applications requiring high-quality, long-lasting prints, such as fashion textiles, home textiles, and other fabric-based products. Reactive inks have the most extensive range of products from entry-level to premium luxury fashion level.

In short, the 3 most important benefits are:

Using reactive inks in your printing process is done with five steps:

Step 1: Pre-treatment

Prepare fabric by applying a pre-treatment.

Step 2: Print

Print your design with an inkjet printer equipped with reactive inks.

Step 3: Steam

Ink fixation into the fabric.

Step 4: Wash

Wash off remaining pre-treatment and ink residue.

Step 5: Finish (optional)

Apply post-treatment and finalize result.

Our experts would like to share their knowledge and experiences with you.

Read all about our Digital Textile Inks and the benefits for your company in our blogs.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.