Production-as-a-Service explained: Easy entry into Printed Electronics manufacturing

Companies across the world are developing innovative printed electronics products that require...

Read moreScaling printed electronics from prototype to series production introduces new risks — tighter tolerances, higher volumes, and less room for deviation. Pyrite addresses one of the most critical variables in this phase: the screen. By delivering controlled, consistent screen precision, Pyrite helps de-risk high-precision functional printing at production scale.

Want to discuss whether Pyrite fits your printed electronics application?

Mesh specifications

405, 305, 215, 195, 190, 185, 165, 160, 135, 130, 125, 105, 100, 80, 75, 40

Repeat sizes seamless

144T, 158T, 167T, 168T, 185T, 189T, 192T, 202T

Repeat sizes welded

96T to 202T

Emulsion thickness

Customer specific

Engraving resolution

50 micron

Full range

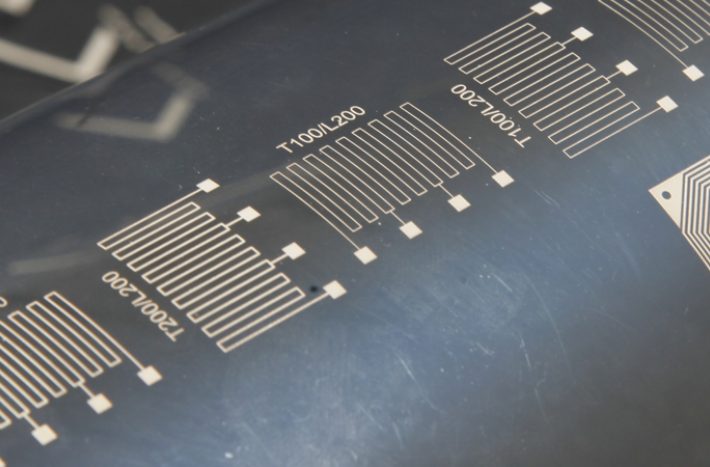

In printed electronics, small variations can directly affect functional performance. When tolerances are tight, the screen becomes a critical variable. Pyrite is developed to reduce this variability by controlling and verifying key screen parameters as applications move into production.

Printed electronics applications demand precise control over line width and ink deposition. Pyrite is designed to support fine-feature printing while maintaining the ink volume required for functional performance. By controlling layer thickness and image definition, Pyrite reduces screen-induced variability and helps stabilise high-precision printing processes.

As production volumes increase, consistency becomes critical. Pyrite supports repeatable results across runs by defining and verifying screen properties upfront. This reduces trial-and-error during scale-up and helps improve first-time-right rates when printed electronics applications transition into series production.

Pyrite builds on SPGPrints’ experience in rotary screen printing for printed electronics. Customers benefit not only from a high-quality screen solution, but also from application knowledge, validation support and access to Production-as-a-Service. This combination helps manufacturers make informed decisions and reduce risk when scaling up functional printing applications.

Our experts would like to share their knowledge and experiences with you.

Read all about Rotary Screen Printing technology for Industrial Solutions in our blogs.

Every printing process is different and the same is true for the challenges you have. We’ve got you covered.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.