FAQ: Frequently Asked Questions about Printed Electronics

In our FAQ, we cover all questions you might have about industrial printing for Printed Electronics.

Read moreDigital pre-press systems for imaging plates, screens and sleeves. These bring enormous performance improvements to manufacturing processes for labels, textiles and numerous industrial printing applications, including wallcovering and pad printing.

Engraving or exposing the perfect plate using the correct pre-press system is crucial to achieve the highest printing quality.

Image quality can be achieved with the use of one of these three different techniques:

The digital pre-press systems can be divided into two groups:

Textile:

Rotary screen-printing for wide web (> 1000 mm). SPGPrints is the only provider of these unique techniques in textile rotary screen printing.

Label and Industrial:

All other industrial and label printing options, flexo, dry offset, pad printing, label printing, narrow web, intaglio, embossing amongst others.

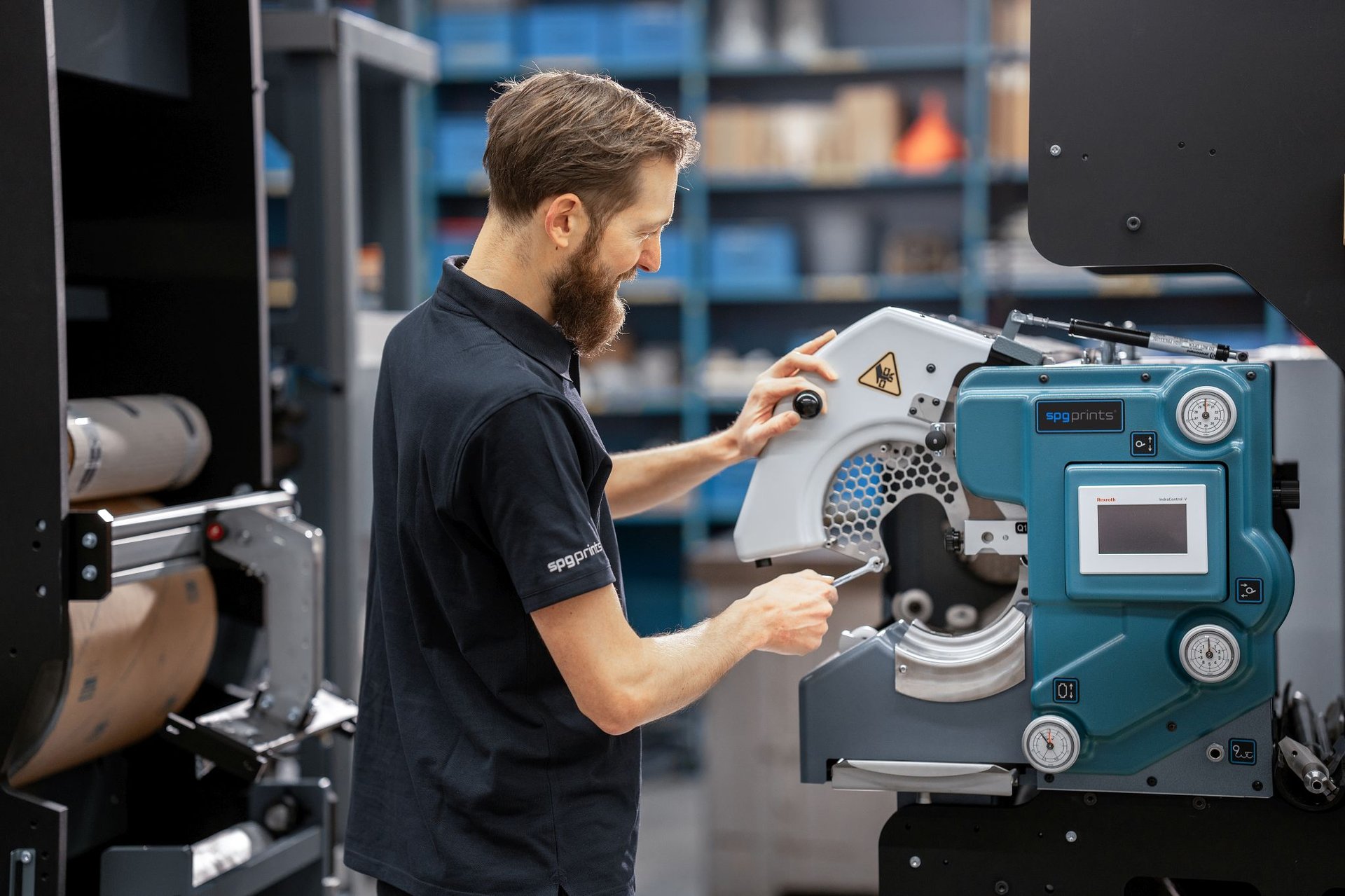

Engineering, development and machine production in Austria, Europe since 1968.

One-stop-shop for maintenance, service and delivery worldwide.

Discover the best solution for your printing challenges.

Fast, cost-effective printing production.

There are many industrial and label printing solutions. Discover the best option for your challenge.

Rotary screen-printing for textile and all other industrial and label printing options: flexo, dry offset, pad printing, rotary screen printing, narrow web, intaglio, embossing etc.

CTP (Computer to plate):

Fibre Diode lasers are used to image the printing form by ablating a black mask or by UV-curing directly (with the use of UV-lasers) a photosensitive lacquer.

DLE (direct laser engraving):

High power CO2 or fiber laser burns away the non-image area of the printing form, which can be polymer, elastomer or lacquer used for rotary screens.

The engraving is controlled by SPGPrints’ proprietary 3D Active RIP software, which also allows three-dimensional dot-shaping to prevent over-impression of smaller elements.

Proud to offer a fully modular, economic and accurate screen-making workflow by conventional method, for narrow-web, mid-web or semi-rotary applications. We offer a wide range of high-end conventional Pre-press Equipment such as:

RotaPlate Dev & Dry system provides a fast, ergonomic and automated means of developing and drying RotaPlate rotary screens, for narrow web applications, in a one-step, quality-assured process. RotaPlate Dev & Dry is an essential tool that completes your CtS system and also improves the quality of your digital pre-press process.

Turn-key solutions for the graphic, packaging and textile Industry.

SPGPrints offers state of the art pre-press systems for a wide range of different applications within the global packaging industry. High quality and high productivity are finally combined with an attractive level of investment.

We are proud to have 75 years of expertise and experience in the printing business. Big international clients are satisfied with our products, knowledge, service and maintenance. We are ready to help you with your industrial or label printing demands to have high quality results to be proud of.

Find out how you can optimize, improve and upgrade your workflow. With high-quality equipment, contracts, maintenance and application support. Receive personal advice from one of our industrial and label printing specialists.

Discover everything about our Industrial and Label Printing solutions.

We are eager to help solve your industrial or label printing challenge, to ensure the highest quality for you and your customers. We’ve got you covered.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.