FAQ: Frequently Asked Questions about Printed Electronics

In our FAQ, we cover all questions you might have about industrial printing for Printed Electronics.

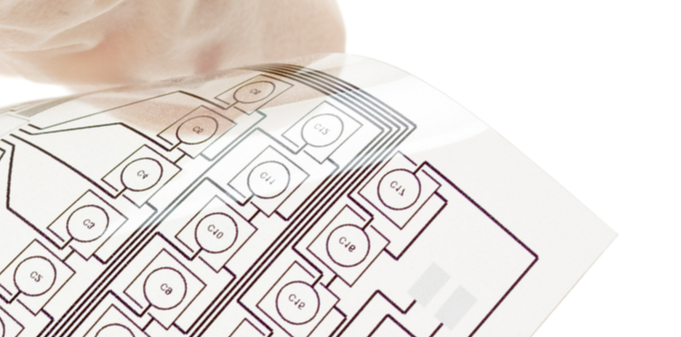

Read morePrinted electronics

The first important difference is pace, directly influenced by continuity. Flatbed screen printing is practically done in 2 strokes. In rotary screen printing, these same steps are combined in a continuous process. Rotary screen printing can use lower squeegee speeds, but achieve the same or even faster output, with a more constant printing result.

For some applications - such as printed circuit boards - Printed Electronics are required to be mass-produced. Rotary screen printing is a rotary process that can run longer than other screen printing techniques. This ensures that the print line can continuously reproduce products at higher volumes.

For screen printing techniques, downtime and clogging of holes are the main deal-breakers. Because the rotary screen printing process is a continuous process the printing result is much more consistent than other screen printing techniques.

A frequently mentioned advantage of rotary screen printing is that the lifespan of screens is relatively high. Although the equipment investment for a rotary screen printing process is higher, less downtime and lower start-up costs result in a much higher lifespan of screens and thus lower costs.

Finally, integration with your existing print line is an important topic for many companies. The integrated implementation of rotary screen printing is fairly easy when compared to flatbed screen printing.

PaaS lets companies interested in high-throughput machines for industrial-scale printed electronics run small batches. SPGPrints recently launched this service to give customers a risk-free way to trial new print technologies and explore benefits before investing. Discover more >>

The total package to meet your needs

Since SPGPrints invented rotary screen printing in 1962, we have taken the concept into many exciting directions. Among the most successful applications in recent years has been printed electronics.

Rotary screen printing is now very commonly used for manufacturing printed electronics. Contrary to flatbed printing, our technology allows for seamless printing, hence, uninterrupted and fast high- volume production.

While the initial investment in rotary screen printing may be substantial the ROI is short because of low running costs and the screens' long lifetime.

Which printing method best suits my production process? How do I save costs without compromising quality? Our Printed Electronics Calculator provides you with answers to these relevant questions and gives tailored insights into an efficient and cost-effective printed electronics production process.

Find out how SPGPrints can help you to meet any challenge and grow your printed electronics business.

Discover everything about our Printed Electronics solutions and more.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.