Screen Printing Techniques for Printed Electronics

What is the best solution for your manufacturing process? Which technique can help you to improve best?

Read moreSPGPrints pre-press systems offers simplified, automated, digital and conventional workflows. Discover our turn-key solutions for industrial applications.

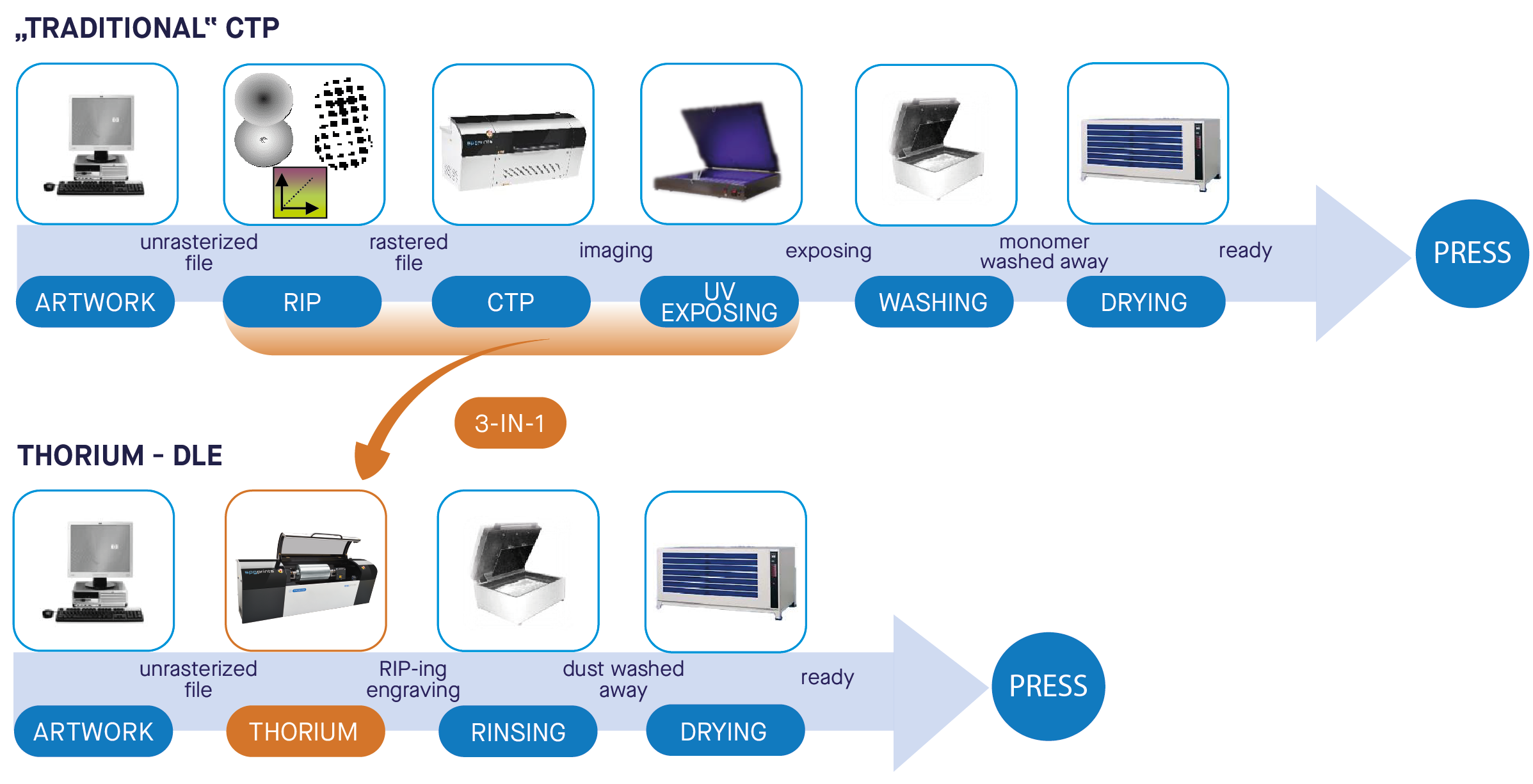

Digital pre-press greatly improves throughput: not only are imaging cycles complete within fast time-frames; it is also possible to image multiple plates at once and producing high quality print form for multiple applications. This means greatly improved handling and logistical efficiencies in your workflow.

Use our direct laser engraving

and direct laser esposing technology - many different applications can be supported with

SPGPrints‘ pre-press systems:

Engineering, development and machine production in Austria, Europe since 1968.

Improve your workflow with maintenance, service, and application support to guarantee high quality.

Any industrial or label printing graphics can be created with our broad range of industrial printing solutions.

Fast, cost-effective printing production technology.

Swift and precise workflows lead to enhanced productivity by optimizing processes and resource utilization.

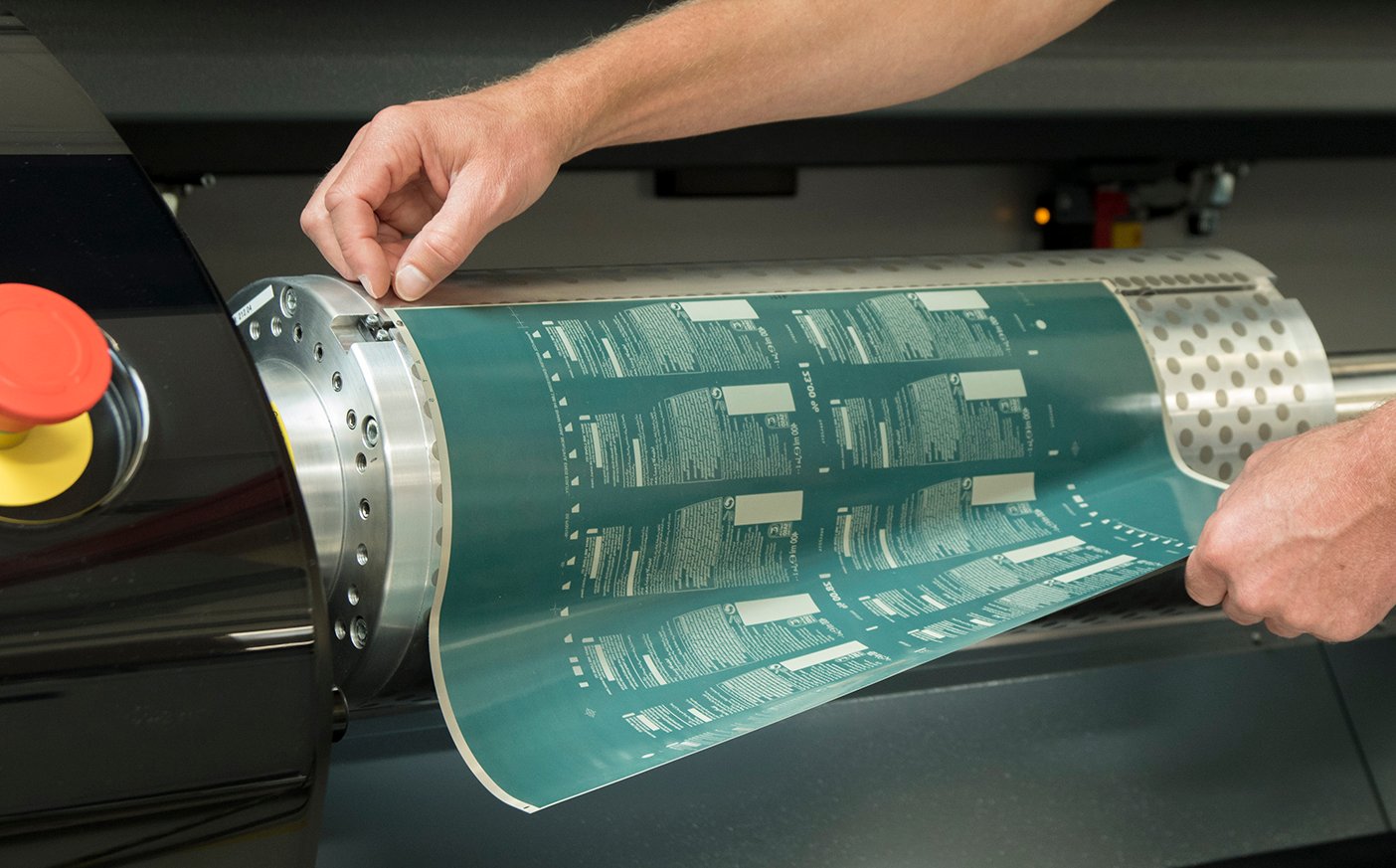

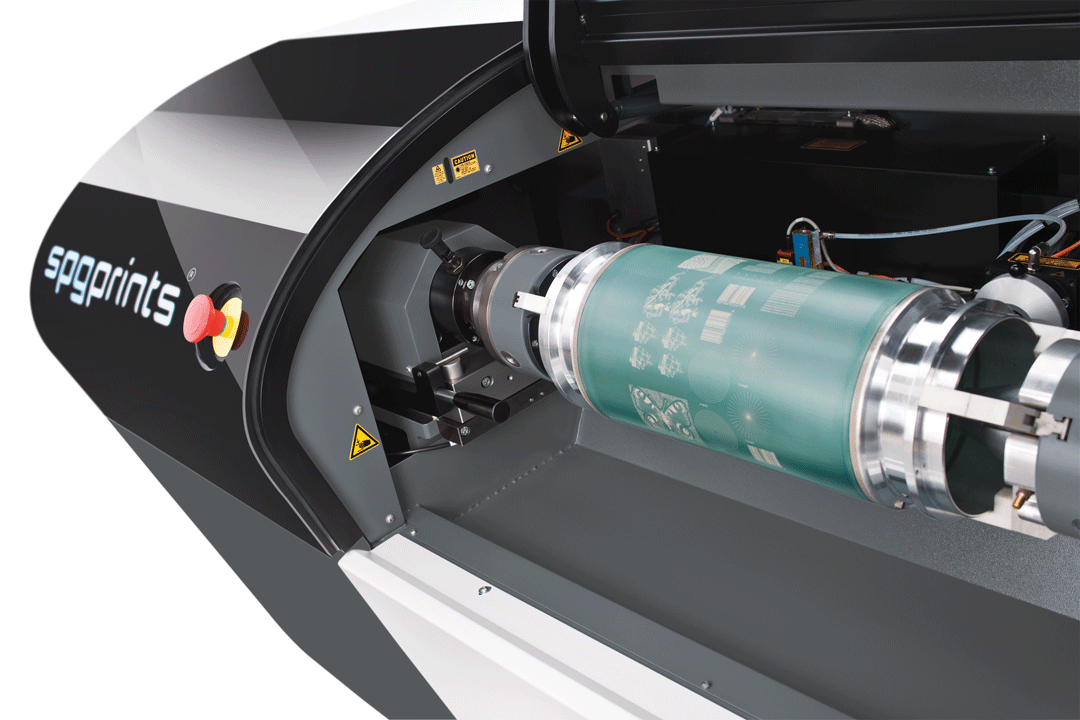

SPGPrints’ DLE solutions stand out due to their exceptional engraving quality. For over 37 years, we have been developing systems that enable precise engraving of plates and seamless printing forms across various applications. Discover our systems:

TITANIUM - Computer to plate - max. plate size 25“ x 30“

The TITANIUM is SPGPrints‘ answer to the need of a multifunctional CTP solution.

PLATINUM - Direct laser engraver

The PLATINUM is SPGPrints‘ answer for companies who need seamless, endless sleeves and rollers.

TITANIUM - Computer to plate - max. plate size 48“ x 35“

The TITANIUM is SPGPrints‘ answer to the need of a multifunctional CTP solution.

IRIDIUM & RHODIUM - Direct laser engraver

IRIDIUM and RHODIUM are specially designed to serve printers in the label, security printing, bio sensors and electronic printing market.

High quality and high productivity are combined with an attractive level of investment. Drawing from over 37 years of experience in imaging systems, SPGPrints has created a solution that truly meets all market needs. The system either ablates material directly (similar to screen printing) or removes a LAMs layer (CTP). Discover our solutions:

Laser technology has revolutionized various industries. Resulting in high quality printing using the best option for your challenge.

In the dry offset industry (indirect printing (wet in wet) of seamless containers like cans, cups, tubes and aerosol cans) SPGPrints is a market and technology leader in pre-press, especially for 2 piece beverage cans. To produce the printing plates either a direct laser engraving system or the computer to plate system can be used.

Flexo plate printing forms are commonly used for packaging materials (foil, paper and labels, tissues). It can be imaged with a CTP system according to the CTP = LAM principle + UV exposure or with the direct laser engraving machines.

Rotary screen printing is commonly used with label and narrow web printing used in order to do opaque white, special effects, embellishments and refining. The RotaPlate® can be used for this application (plate material that is sealed to an in-the-round printing sleeve after exposing). For imaging and exposing different units can be used:

A welded in-the-round screen is used by RotaMesh®. For engraving and exposing RotaMesh® following units can be used:

Letterpress is now only seldom used for printing narrow web and labels. Letterpress plates are thin plates that either have a foil back or metal back. As the metal back plates are the same plates that are used for dry offset printing, the terms letterpress and dry offset are often mixed up. Plates for letterpress can be either engraved with DLE or imaged using our CTP devices.

For embossing effects in (mainly) paper, hard ‘printing’ plates, sleeves or rollers are used. For sleeves and roller a DLE system is needed. Only a DLE system offers the possibility to do special 3D- effects. Known products where embossing is used are book-covers and posters but also beverage cans can be embossed.

Explore the possibilities of SPGPrints’ digital pre-press systems, which offer shortened and seamless workflows thanks to perfectly coordinated software and hardware. All systems from SPGPrints are equipped with a digital database which stores different calibrated material specifications. This reduces the chance of human errors and increases the efficiency in the whole workflow.

We provide you with the optimal solution for your pre-press needs. Find out how you can optimize, improve and upgrade your workflow. With high-quality equipment, contracts, maintenance and application support. Receive personal advice from one of our industrial and label printing specialists.

Discover everything about our Industrial and Label Printing solutions.

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.