Exploring FESPA 2024: Trends in Digital Printing and Sustainability

Last week, we proudly showcased our booth at FESPA 2024. Close to our head quarters this time, as this year's edition took place in Amsterdam. The exhibition ...

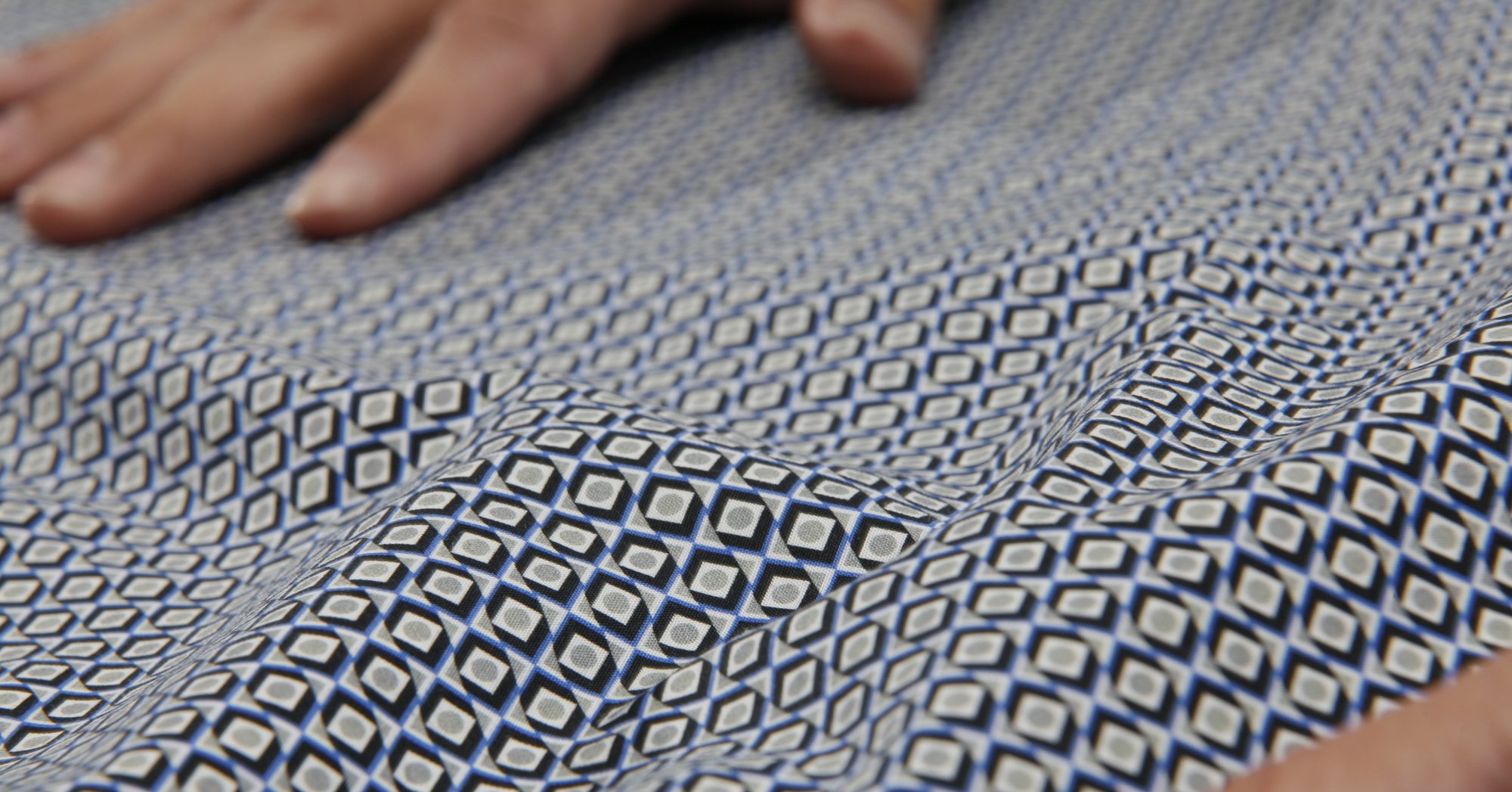

To translate complex designs into fabric prints of the highest quality, operators and printing managers must select the correct type of rotary screen. In this...

Transferring production to digital printing used to demand a significant investment – and a steep and sometimes scary learning curve – but things are changing....

To achieve optimal efficiency, reliable runnability for your printing process is crucial. This is always the case, but it is particularly important for digital...

Last week, we proudly showcased our booth at FESPA 2024. Close to our head quarters this time, as this year's edition took place in Amsterdam. The exhibition ...

Our recent participation as exhibitors at LOPEC 2024 was nothing short of exciting. Amid the lively atmosphere, our booth drew significant attention, with ...

Heimtextil 2024 has come and gone, and SPG Prints is delighted to have been part of this prestigious trade fair in Frankfurt this year. Our booth was a hub of ...

Gain insights about the industry and in-depth knowledge.

Stay up to date

1 newsletter a month.

The Consumer Electronics Show (CES) in Las Vegas is renowned for unveiling the latest technological marvels, and we at SPGPrints were naturally eager to ...

Fluorescent dye-sublimation printing has brought about a radical transformation in the domain of digital printing. It introduces exhilarating prospects for the ...

Fluorescent dye-sublimation printing has revolutionized the world of digital printing, offering exciting new possibilities for transforming fashion, sportswear ...

Digital sublimation printing is an interesting option for many textile industries. Not only is the printing process more straightforward and requires less ...

Choosing the perfect rotary screen depends on many factors. Still, it is a very important choice. Whether you print with an appropriate rotary screen ...

How your product looks, and the quality of its labelling can make or break its success on the store shelf. Packaging design and print quality are key ...

Europe produces an incredible 61 billion drink beverage cans annually, with brand owners investing in more complex and elaborate HD-designs to stand out on the ...