Label printing

Add an exciting new dimension to your label printing capabilities

We offer you the best label printing benefits

Add an exciting new dimension to your label printing capabilities

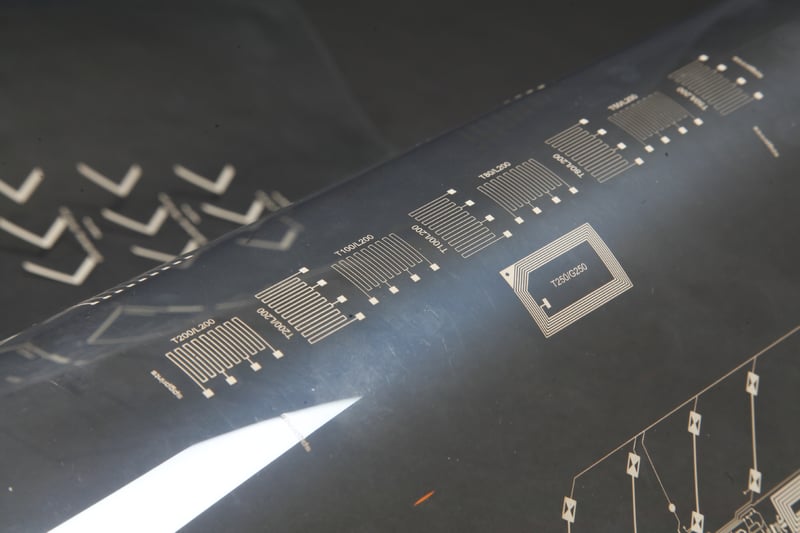

Are you looking for ways to make your labels even more powerful as purchasing motivators? With SPGPrints you can complement your printing process with the ability to apply ink layers in thicknesses (up to 250 micrometer) that could never be achieved with other techniques.

Give your wine labels the embellishments they deserve

The more classy the wine label, the more customers are willing to spend. With our rotary screen printing technique you can apply thick layers of varnish so that label details will be raised in 3D to great effect

Make your transparent self-adhesive labels shine

For transparent self-adhesive labels as used on packaging for, e.g., shampoos and healthcare products, our rotary screen printing technique will allow you to apply an opaque white ink layer that is the ideal basis for making colors shine.

We will help you every step of the way

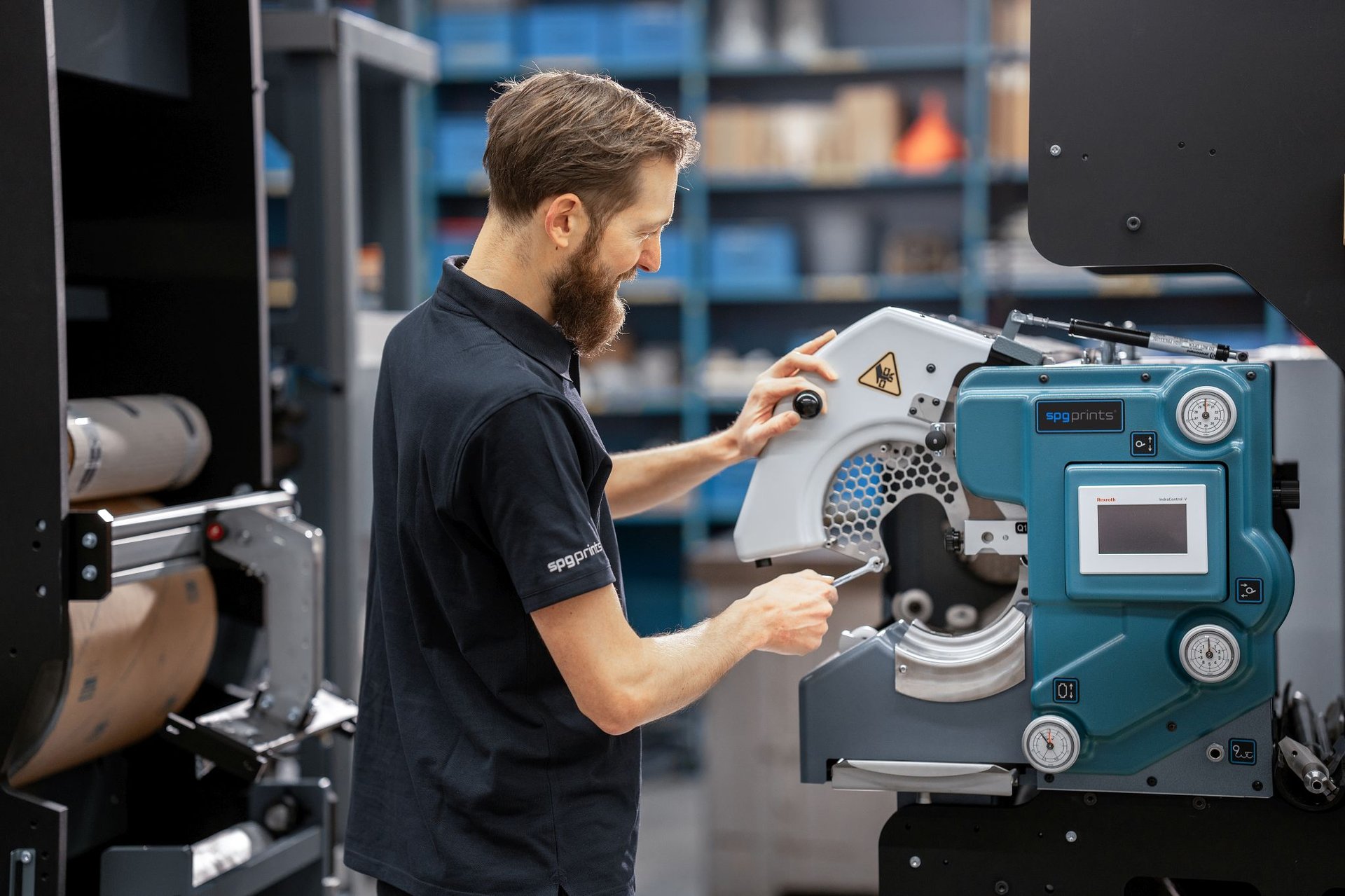

Our specific application expertise is unrivaled worldwide. Our specialists will help you to overcome any obstacle you may encounter when integrating rotary screen printing into your process.

A unique total solution to expand your business potential

The total package to meet your needs

The SPGPrints portfolio features special rotary screens to suit your purpose. Whether what you're looking for is primarily stability and durability, or speed and economy, we have got you covered.

SPGPrints can supply a complete rotary screen printing module that is easily integrated with your existing label, flexo or offset press. Our Rotary Screen Integration (RSI®) units are designed to permit great flexibility in placement on your machine.

The SPGPrints portfolio also includes digital laser engraving machines for manufacturing your own rotary screens. The highest degree of consistency is guaranteed.

The pleasure of doing business with a trusted partner

Besides helping label printers all over the world to add rotary screen printing to their existing printing process, we are the global number one supplier of rotary screen printing modules to OEM label press manufacturers. All in all 80% of all machines used for this specific purpose are SPGPrints RSI® units.

Let's talk about your challenge

Find out how SPGPrints can help you to meet any challenge and grow your business.

Other SPGPrints applications

We aim to bring colour to the world. Our experience, knowledge, understanding of businesses and true partnership have earned us many loyal customers.